Would you drive without a seatbelt? Of course not. Then why risk working long shifts without proper footwear? Safety shoes aren’t just another piece of equipment; they’re a daily safeguard for your health, mobility, and career.

From clunky iron-capped boots of the 19th century to today’s lightweight, breathable, multi-purpose protective footwear, the evolution of safety shoes tells a story of progress. Modern boots combine advanced materials, ergonomic design, and compliance with strict international standards.

This article is designed as the definitive guide. Whether you’re in construction, healthcare, logistics, or farming, here you’ll find everything: safety footwear standards, classifications, profession-specific recommendations, health aspects, care tips, and replacement guidelines. If you’ve ever wondered how to choose the right pair or why your feet still hurt even in protective boots, keep reading.

Understanding Safety Footwear Standards and Classifications

Global and European Standards

The cornerstone of safety footwear in Europe is EN ISO 20345. It defines minimum requirements, including toe protection against 200-joule impacts. Without this certification, a shoe simply isn’t a safety shoe.

Main classes explained:

- S1: Closed heel, antistatic, fuel oil resistance, energy absorption.

- S1P: Adds puncture resistance.

- S2: Adds water penetration resistance.

- S3: Combines S2 with puncture-resistant midsoles and cleated outsoles.

- S4: Polymer/rubber boots, waterproof, antistatic, oil resistant.

- S5: S4 plus puncture resistance and cleats — perfect for mud or construction.

Specialty Markings

Beyond classes, extra markings adapt footwear to specific risks:

- P: Puncture resistance.

- C: Conductive.

- CI: Cold insulation.

- HI: Heat insulation.

- HRO: Heat-resistant outsole.

- ESD: Protection against electrostatic discharge.

Think of these as “bonus shields” — tailored armor for your feet.

The German Context

Navigating the market for Safety shoes in Germany means more than just picking a pair off the shelf. German workplaces are regulated with remarkable precision. Employers insist on compliance not only with EN ISO 20345 but also with national BG (Berufsgenossenschaft) requirements.

In many German companies, occupational physicians and safety managers even help select footwear. Buying random boots online without certification may result in being barred from work or even fined. For professionals searching Sicherheitsschuhe kaufen Deutschland, knowledge of standards isn’t optional — it’s essential.

Choosing the Right Safety Shoe for Your Profession

Construction & Heavy Industry

Imagine walking across a site littered with nails and heavy machinery. Here, S3 boots are the baseline: robust leather uppers, steel or composite toe caps, puncture-resistant midsoles. Waterproofing and ankle support are critical.

Logistics & Warehousing

Workers in warehouses often walk 10+ kilometers daily. Heavy boots are exhausting. The smarter choice is S1P shoes — lightweight, breathable, but still protective. Add slip-resistant soles for busy loading docks.

Healthcare & Hospitality

Nurses, cleaners, chefs: long hours, slippery floors. The focus is on hygiene, slip resistance, and cushioned soles. Standards O1 or O2 often fit best, especially with washable microfibers. Comfort and hygiene trump steel caps here.

Manufacturing & Automotive

Factories bring electrical risks and chemicals. ESD work shoes are essential to avoid damaging sensitive electronics or sparking accidents. Rubber or special coatings protect against chemicals. Ankle stability reduces fatigue in repetitive tasks.

Outdoor & Agricultural Work

Farmers, landscapers, and utility workers need S5 boots: fully waterproof, thermally insulated, with aggressive tread. Without them, frostbite, slips, or wet feet become daily battles.

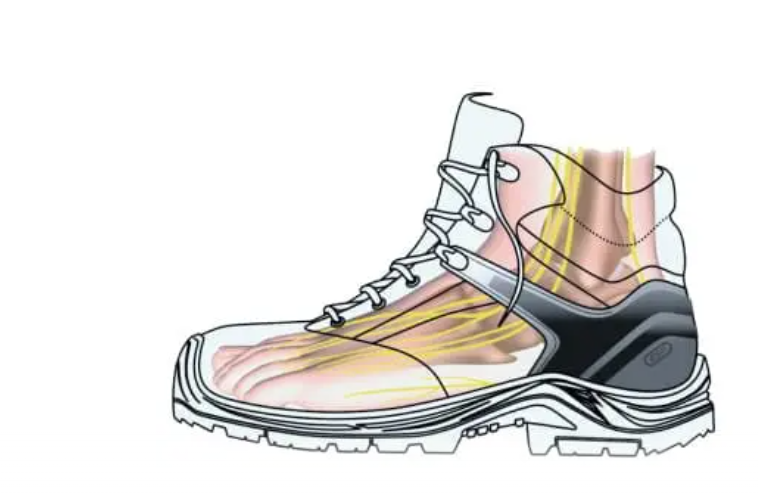

The Human Factor: Comfort, Fit, and Foot Health

The Right Fit

Feet swell as the day goes on. Trying boots in the morning? Mistake. Always test them late afternoon. Leave enough space at the toes — about a thumb’s width. Poor fit doesn’t just hurt; it leads to bunions, back problems, and long-term injuries.

Insoles and Arch Support

Most stock insoles are thin and generic. Long shifts demand more. Orthopedic insoles for safety footwear support arches, reduce heel pain, and prevent plantar fasciitis. Think of them as shock absorbers for your body.

Material Matters

Leather: breathable, durable, molds to your feet.

Synthetics: lightweight, cheaper, less breathable.

Microfiber: washable, durable, lighter than leather.

Each has pros and cons. The “best” depends on your workplace, not fashion.

The Dangers of Cheap Footwear

Tempted by budget models? Remember: cheap boots wear out quickly, fail safety standards, and cause injuries. Lost productivity, medical bills, and replacements end up costing far more.

Maintenance, Care, and Longevity

Daily Care

- Remove insoles and air shoes.

- Wipe dirt and moisture.

- Rotate pairs if possible.

Deep Cleaning and Conditioning

- Leather: Brush, mild soap, condition with cream.

- Synthetics: Gentle wash, air dry.

- Rubber: Rinse after chemicals or mud.

Storage

Cool, dry, ventilated place. Shoe trees help retain shape. Avoid damp lockers.

When to Replace

Clear signs: worn tread, cracked uppers, damaged toe caps, or compressed midsoles. For most professionals: every 12–18 months, sooner for heavy use.

Safety shoes aren’t just boots — they’re silent guardians of your career. From safety footwear standards to profession-specific advice, comfort, and care routines, this guide showed how to choose wisely and maintain effectively.

Investing in quality footwear means fewer injuries, less fatigue, and more productivity. Your feet carry you through every shift. Protect them, and they’ll carry you confidently toward a safer tomorrow.